Not an industrial recycling mega factory but a grass roots initiative to help save our planet.

We use a low tech and local approach to help be part of the solution with global plastic waste problem. Our intent is not to be a mega corporate recycler but an impactful, community-driven producer who helps remove plastic waste from the community whilst using our global reach to provide a beautiful product loved by consumers worldwide.

We simply help join the global dots from waste plastic thrown away on a beach or burnt in an incinerator as we transform it into a beautiful and practical product used by people in London, Singapore, New York or Israel.

Collection

We work with food manufacturers to collect plastic waste (pre-consumer) that has been rejected as part of their manufacturing process. Local community members are paid to collect waste plastic from around their village, the roadside or local beaches. Also, amazing community members collect their own waste plastic generated by their household and bring it to us for recycling.

Sorting

We work by hand to sort and clean the waste plastic brought in. This involves sifting through the raw material for the different plastic types and grouping together (as best we can) the same or similar colours.

Shredding

Our plastic waste is shredded into small pieces ranging from 2mm and up to 4-5mm in size. We then store our ‘shreddies’ in bags ready for processing into our products. This allows us to generally influence the overall colour of our products from more reds, blue, greens, etc. By its nature, using plastics containing a reflective or foil like finish often results in a reflective, eye-catching sparkle that is unique to every single one.

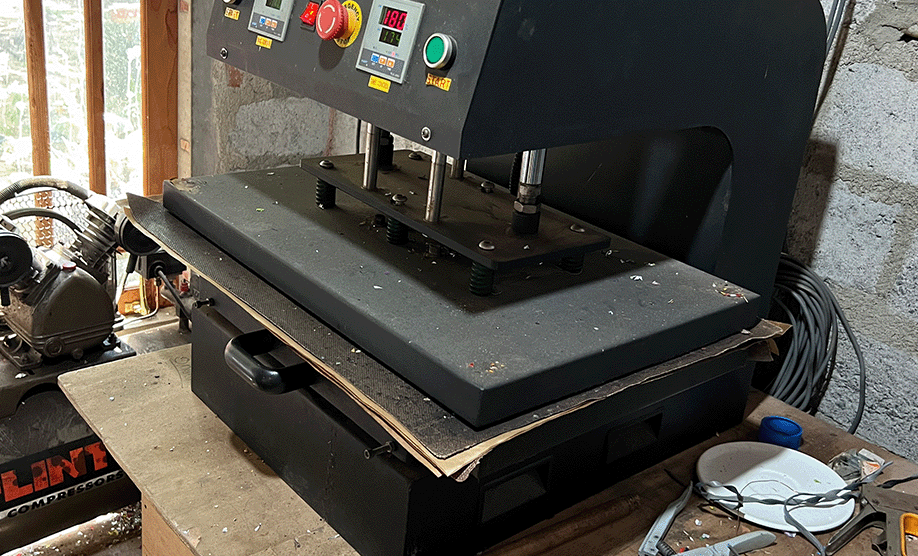

Heat Press

We lay the shredded plastic onto an A1 size sheet with a small frame around the outside and smooth the shredded plastic out into the thickness we require. These are wrapped in heat resistant material and carefully placed into our Heat Press.

Transformation

Using the simple principal of thermoplastics, we heat the plastic to temperature and after a few minute our plastic shred is transformed into a plastic sheet. Once cooled with have beautiful sheets of plastic ready for use.

Product Creation

Using simple hand tools we cut our plastic sheet down to size – A4 or A5 for our notebooks or into our placemats. Using a binding machine, we punch holes in the plastic (we even recycled the plastic cut out from the holes) and add our elephant dung paper to create your one-of-a-kind notebook.